Hot Gas Filtration

Release Time:

2025-08-06

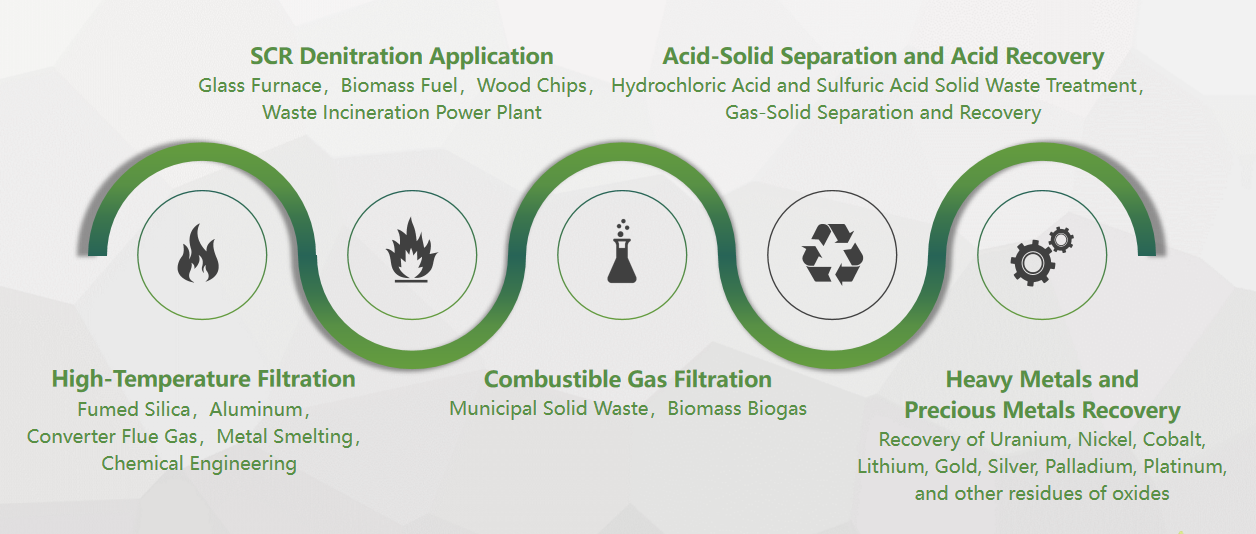

Hot gas filtration technology primarily relies on high-temperature ceramic fiber filters. Endowed with characteristics such as high temperature resistance, strong chemical stability, excellent corrosion resistance, high filtration precision, and moderate mechanical strength, these filters are widely applied in scenarios requiring gas-solid or liquid-solid separation under high-temperature environments. Applications include high-temperature filtration, denitration, combustible gas filtration, acid-solid separation, heavy metal recovery, etc. With excellent and outstanding performance, they have been unanimously praised by customers in the industry. In previous cooperation cases, high-temperature ceramic fiber filters have all demonstrated strong filtration performance.

The flue gas temperature of glass furnaces typically reaches 600-1200℃. During high-temperature reactions, glass raw materials (such as silica sand, soda ash, and sodium sulfate) generate flue gas containing acidic gases (e.g., SO₂, HCl), alkali metal vapors (Na₂O, K₂O), and fluorides, accompanied by ultrafine dust (with particle sizes as small as 1-5μm) and unreacted raw material particles. High-temperature ceramic fiber filters effectively control the dust emission concentration of glass furnaces while reducing heavy metal emissions in the flue gas. By purifying the flue gas, they reduce dust deposition, lower the dust concentration in the workshop environment, improve the operating environment, and indirectly increase the yield of glass products, thus serving as key technical equipment for glass enterprises to achieve green production and cost reduction with efficiency improvement.

In the cement production process, the temperature of flue gas emitted from the kiln inlet and kiln outlet typically reaches 300-800°C, containing a large amount of dust and corrosive gases. Traditional baghouse dust removal equipment struggles to operate stably for a long time. However, high-temperature ceramic fiber filters, relying on their excellent temperature resistance and filtration efficiency, effectively reduce the system's footprint, increase dust removal efficiency to over 99.9%, extend maintenance intervals, significantly reduce downtime, and efficiently achieve dry dust removal. There is no need for water spraying or cooling, thus avoiding secondary pollution caused by wet dust removal.

Waste incineration flue gas contains acidic gases, dioxins, and heavy metal particles. High-temperature ceramic fiber filters can be equipped with catalysts to achieve dry denitrification and desulfurization via catalysts, filter harmful substances such as dioxins and heavy metal particles. They operate continuously at high temperatures, stably control flue gas emissions, effectively capture particulate matter in the flue gas, and inhibit the reformation of dioxins. Additionally, the filters have a long service life and low maintenance costs.

The flue gas temperature of medical waste incinerators typically reaches 600-800°C. Medical waste incineration generates acidic gases such as HCl, SO₂, and NOₓ, as well as vapors containing heavy metals like mercury, lead, and cadmium. It also contains a large amount of ultrafine dust particles (with particle sizes as low as 1-5μm). Moreover, medical waste has complex compositions (including volatile substances such as plastics and rubber), so the flue gas temperature may fluctuate within a short period during incineration.