Understanding Temperature Parameters of Ceramic Fiber Filter Elements: The Key to Ensuring Stable Operation of Industrial Flue Gas Filtration

Release Time:

2025-08-20

In industrial flue gas filtration, understanding the long-term operating temperature and short-term impact temperature of high-temperature ceramic fiber filter elements is key to selection. It is necessary to distinguish between the material's fire resistance grade and the actual operating condition temperature, ensure that the operating condition temperature is matched, and avoid over-temperature operation, so as to safeguard stable equipment operation and the service life of filter elements.

In the field of industrial flue gas filtration, high-temperature resistant ceramic fiber filter elements, with their excellent ceramic-like properties such as high temperature resistance and acid-alkali resistance, play an irreplaceable role in industries such as high-temperature flue gas environmental protection treatment, metal smelting filtration, precious metal recovery, high-salt wastewater emission reduction, high-temperature flue gas heat recovery, and carbon emission reduction. To ensure the stable and efficient operation of filter elements in actual working conditions, accurately understanding their temperature resistance parameters during selection is an important prerequisite. Among them, long-term operating temperature and short-term impact temperature, as core parameters, are the first and crucial step in reasonably selecting filter elements, directly related to the performance and service life of ceramic fiber filter elements in actual working conditions.

Long-term Operating Temperature: The "Normal Safety Line" for Stable Filter Operation

Long-term operating temperature refers to the maximum temperature threshold at which ceramic fiber high-temperature resistant filter elements can maintain structural integrity, filtration performance, and mechanical strength under long-term, continuous working conditions. This is the "safety red line" for filter elements in conventional working conditions. Once the actual operating temperature exceeds this value, the filter performance will decline irreversibly.

From the perspective of material essence, the type and composition of ceramic fibers are the core factors determining the long-term operating temperature. Different types of ceramic fibers have significantly different high-temperature resistance properties: alumina fibers have a relatively high long-term operating temperature due to their high melting point and stable chemical properties; while the long-term temperature resistance range of aluminosilicate fibers is affected by the ratio of silicon dioxide to alumina in their composition, with the temperature range changing accordingly with different ratios.

It should be particularly noted that ceramic fiber filter element product descriptions often mention performance indicators such as "temperature resistance up to 1260℃", but this value actually refers to the fire resistance of the refractory fiber material itself.

According to national ceramic fiber standards, the actual long-term operating temperature of filters made from fibers meeting the 1260℃ fire resistance grade is much lower than this value, usually needing to be controlled below 650℃. The reason is that 1260℃ grade ceramic fibers are mainly composed of alumina and silica, which exist in a free-state structure. When the temperature exceeds 650℃, the free-state structure will slowly undergo crystalline phase transformation, leading to a gradual attenuation of the filter element's structural strength. The higher the temperature, the faster the attenuation rate. This characteristic determines that 1260℃ grade ceramic fiber materials are not suitable for long-term use in environments above 650℃. If exposed to such temperature ranges for a long time, the filter element will gradually be damaged due to continuous strength attenuation, resulting in a significant decline in filtration efficiency, failing to meet industrial production requirements for filtration accuracy and stability. It may also cause irregular breakage of the filter element due to insufficient strength, increasing maintenance frequency. This profoundly reflects the essential difference between the material's fire resistance grade and the actual long-term operating temperature of the filter element, which is a key focus during filter element selection.

Short-term Impact Temperature: The "Emergency Guarantee Value" for Coping with Sudden High Temperatures

Short-term impact temperature refers to the maximum temperature that ceramic fiber high-temperature resistant filter elements can withstand within a short period (usually several minutes to several hours). This parameter is mainly used to cope with possible sudden high-temperature situations in working conditions, such as temperature fluctuations at the moment of equipment startup or brief overheating during the production process.

Unlike long-term operating temperature, short-term impact temperature does not require the filter element to work stably at that temperature for a long time; the core is to ensure that the filter element does not suffer structural damage under short-term high-temperature impact. The value of this parameter is also closely related to the material and manufacturing process of ceramic fibers: high-quality ceramic fibers, after special treatment, can resist higher temperature impacts for a short time and maintain the basic shape and filtration function of the filter element.

In practical applications, clarifying the short-term impact temperature is of great significance for dealing with sudden working conditions. For example, in industrial production, if instantaneous temperature rise occurs due to operational errors or equipment failures, if the short-term impact temperature of the filter element can cover this sudden value, it can buy time for fault diagnosis and emergency measures, reducing losses caused by filter element damage.

Core Principles for Selecting High-Temperature Ceramic Fiber Filter Elements

Long-term operating temperature and short-term impact temperature are not isolated but interrelated and mutually influential: filter elements with a higher long-term operating temperature generally have a relatively higher short-term impact temperature due to their material's stronger high-temperature resistance foundation.

During the filter element selection process, it is necessary to comprehensively consider the matching degree between these two parameters and the actual working conditions.

Firstly, it must be ensured that the normal operating temperature of the equipment is within the long-term operating temperature range of the filter element, which is the basis for the long-term stable operation of the filter element. Taking 1260℃ grade ceramic fiber filter elements as an example, they cannot be used in environments close to this temperature for a long time simply because their material fire resistance grade reaches 1260℃. Instead, they should strictly follow the actual long-term operating temperature requirement of <650℃, resolutely avoiding long-term exposure to filtration environments above 650℃ to achieve maximum efficiency and optimal service life.

Secondly, it is necessary to fully evaluate the maximum possible short-term impact temperature in on-site working conditions and ensure that the short-term impact temperature of the filter element can cover this value, so as to effectively handle abnormal situations and minimize losses when emergencies occur.

It should also be clearly noted that even if the filter element can withstand short-term high-temperature impacts, it cannot be used in working environments exceeding the long-term operating temperature range. Frequent high-temperature impacts or long-term operation beyond the long-term operating temperature will accelerate filter element aging and damage, shortening its service life.

In summary, accurately understanding the long-term operating temperature and short-term impact temperature parameters of high-temperature ceramic fiber filter elements is crucial for correct selection, ensuring stable equipment operation, and reducing production costs. In practical applications, comprehensive consideration of specific working conditions is required, especially for materials with clear characteristics such as fire resistance grades, to accurately grasp their actual operating temperature requirements and select the most suitable filter element products.

Advantages of Tianya Ceramic Fiber Filter Elements

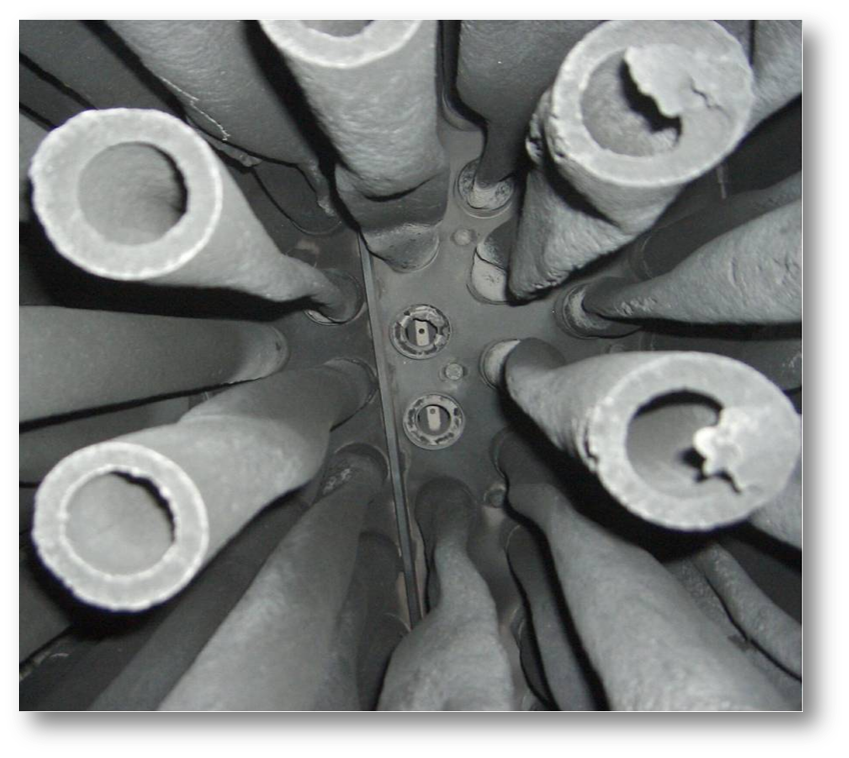

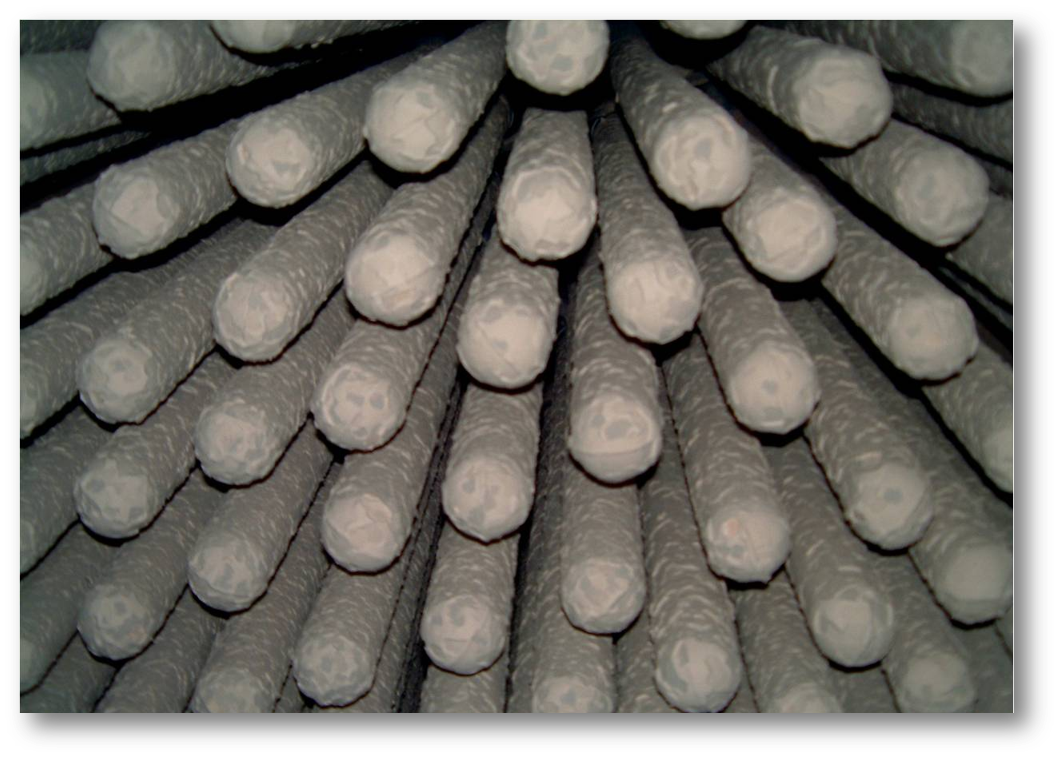

In industrial high-temperature filtration scenarios, the shortcomings of ordinary ceramic fiber filter elements are limited by backward process design. Such filter elements have extremely poor structural stability—when frequently exposed to short-term high-temperature impacts, the structural strength between fibers attenuates rapidly, and structural damage is irreversible. Minor issues include filter element deformation and pipe bending, while severe cases involve direct fragmentation and collapse. This not only leads to a sharp decline in filtration efficiency but also requires frequent shutdowns for replacement due to short service life (often far below the expected cycle), which invisibly increases the equipment loss costs and production interruption risks of flue gas filtration. The following pictures show scenarios in actual production where ordinary filter elements bend and fragment after withstanding multiple high-temperature impacts due to backward processes.

In contrast, Tianya high-temperature ceramic fiber filter elements have achieved a comprehensive breakthrough over traditional products through process upgrades and scientific material proportioning. Relying on optimized process architecture design, the structural strength of the filter element has achieved a qualitative leap: under the same temperature resistance grade, the comprehensive performance is more than 1.6 times that of ordinary filter elements, greatly alleviating the structural fragility of traditional filter elements under high-temperature impacts.

In terms of core indicators, the advantages of Tianya filter elements are particularly significant: the service life of the filter element reaches 5 years or more, significantly reducing the labor and material costs of frequent replacements. Benefiting from the dual support of high-quality fiber materials and advanced processes, the filtration efficiency of the filter element remains stable and excellent, with maintenance frequency and costs reduced to an extremely low level. More importantly, when facing sudden high-temperature fluctuations or changes in working conditions, Tianya filter elements, relying on strong structural stability and impact resistance, can effectively resist structural damage under extreme conditions, minimize losses from production interruptions, and build a solid defense for the safe and continuous operation of industrial filtration, truly achieving low-cost and efficient operation characterized by "one-time investment, long-term peace of mind".